limitations of rockwell hardness testing|rockwell hardness testing machine diagram : Brand manufacturer The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a slight error in measuring the depth difference can result in a significant error in the calculated hardness value.

Resultado da Encontre os melhores jogos de slots e muito mais na Croupier. Cadastre-se agora e comece a jogar!

{plog:ftitle_list}

12 de nov. de 2023 · 2:03. Leylah Fernandez led Canada to its first-ever Billie Jean King Cup win — the most prestigious tennis title in women's international team play. The 35th-ranked Fernandez, who hails from .

What is the Rockwell Hardness Test? Rockwell Hardness Test Procedure: A Step-by-Step Guide. How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness . Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . Rockwell hardness testing is a common analytical technique for evaluating the hardness of metallics and synthetic materials. Rockwell Hardness Test. While hardness testing does not provide a direct assessment of product .

On a manually operated unit, a Rockwell test takes only five to ten seconds, depending upon the size and hardness of the specimen, as well as pre-load and dwell time. Also, the indentation is .

The Rockwell method has the following disadvantages: It is not always the most accurate hardness testing method, as even a slight error in measuring the depth difference can result in a significant error in the calculated hardness value.The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional . Failure to properly prepare and execute a Rockwell hardness test can result in compromised test data or false readings, potentially contributing to the production and delivery of substandard product. This could have .The disadvantages of Rockwell hardness test include the possibility of causing damage to the material surface during indentation, its limitation in testing very soft or very hard materials, and its inability to provide accurate results for .

The Rockwell Hardness Test also uses superficial scales. These use lower loads and shallower indentions and are useful when a sample may be too brittle or thin for a standard Rockwell hardness test. Superficial Rockwell . The Rockwell Testing systems depend on the material that is being tested including the hardness, thickness, indentation positioning, and scale limitations on the materials that are being tested. The material being tested . Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . • Scale limitations . Principle of the Rockwell Test . The Rockwell principle is described as follows: An accurately shaped indenter is used to make an indent in the sample to be tested. This indenter is either a spheroconical diamond, a 120-degree .V. Limitations of Rockwell Hardness Test. With all the huge benefits of easy set-up and speed of testing and result acquisition that Rockwell hardness testing offers, its information will be incomplete without stating its limitations. One major limitation is the indenter travel which is often limited to 0.2mm or 100 Rockwell points.

Digital Thickness Meter tv shopping

Advantages and Disadvantages Of the Rockwell Hardness Test. The Rockwell hardness test is a widely adopted method for evaluating the hardness of materials, especially metals. It provides numerous advantages that have made it a preferred choice across various industries. However, it's crucial to acknowledge its limitations and potential drawbacks.Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.The factors concerned include hardness level (and scale limitations), specimen thickness, size and shape of the workpiece, specimen surface flatness and surface condition, and indent location. The article focuses on the selection for specific types of materials, such as steels, cast irons, nonferrous alloys, and plastics, and industrial .

Scale limitations; Rockwell Test Techniques - Test Scale . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. .

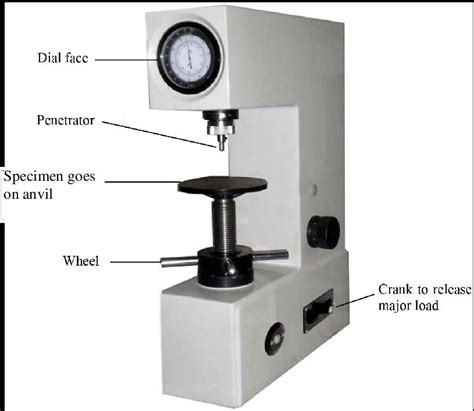

Rockwell Hardness Testing Theory. Rockwell hardness testing has several indenter types which in turn require separate major loads (kg). Figure 1 reflects common Rockwell scales used and their corresponding major loads. Figure 1. When Rockwell hardness testing, a minor load of 10kg is applied to the indenter used on the material being tested.The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .Advantages and Disadvantages Of the Rockwell Hardness Test. The Rockwell hardness test is a widely adopted method for evaluating the hardness of materials, especially metals. It provides numerous advantages that have . Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use .

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an .Rockwell hardness testing is measured using the Rockwell hardness scale with the method defined in ASTM E18 and BS EN ISO 6508-1. Rockwell hardness testing is performed with an indenter of a specified size applied with a specified force for a fixed amount of time. A small Tungsten steel ball (HRBW method) is used to penetrate soft materials . Disadvantages: Applications: Load Range (kgf*) Indentation Type: Standards: Rockwell C (HRC) Metals, Alloys: Quick, easy to use, widely recognized: . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. .

rockwell hardness testing procedure pdf

rockwell hardness testing procedure

Surface Test Only: The Rockwell test can only measure the hardness of the material’s surface. It cannot provide information on the deep hardness of the material. Thickness Limitations: Material thickness and shape may affect test results. .These include the type of test material, the test material thickness, the test material area or width, the test material homogeneity, and the limitations of each Rockwell scale. 3.1.1 Type of Test Material Table 1 lists the typical types of materials that are suitable for testing on each of the thirty Rockwell hardness scales. Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other .

The speed of the method is not very efficient relative to Brinell or Rockwell hardness test. Apart from the time which is consumed for the preparation of the test, it takes almost a minute to complete its cycle. . Every hardness test has its own advantages and limitations. In this article, the Vicker hardness test with its significance . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. . Traditional hardness measurement is only applicable to large-sized samples, not only due to limitations of .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. . The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your right:

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

Digital Plastic and Rubber Thickness Meter tv shopping

WEBThis means that Cracovia Kraków is the 14th best defence in this season’s Ekstraklasa. In the 18 matches it has played in the Ekstraklasa, Legia Warszawa has conceded 21 goals. This means that the team conceded, on average, 1.17 goals per match, making it the 4th team in terms of defensive ability in the competition.

limitations of rockwell hardness testing|rockwell hardness testing machine diagram